|

| Sanitary sewer overflows cause environmental damage. |

Urban development generates an increased volume and frequency of sanitary sewer overflow and damages the environment by allowing the propagation of contaminants and pathogens. To correct these problems, we must first understand the magnitude of these events in order to provide the proper resource is depending on the severity of each situation.

|

| FlowMade |

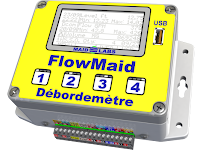

Maid Labs, a manufacturer of innovative and high quality flow meter products, has instrumentation that simplifies the measurement and recording of CSO or SSO volume loss. These Maid Labs products offer treatment facilities extremely simple operation and data logging. Precious time is not wasted learning complex software, converting data or creating reports.

The Maid Labs FlowMaid level monitor, open channel flowmeter and data logger generates the

required reports directly on the USB drive in and Excel compatible format. The FlowMade records the CSO or SSO volume loss into reports using one of the many industry standard full algorithms incorporated by Maid Labs engineers.

|

| MaidMaps |

The FlowMaid is a small monitoring device used to record level, flow, volume and discrete events. It calculates the volume lost in a SSO event using the Manning equation. As an open channel flow meter, the user can select from 11 flow formulas. The only requirement is to enter the level of the overflow pipe, its diameter, material and angle. Years of data can be recorded before filling its memory. Every event shows start and end time, duration, average flow and volume lost.

For more information, contact Advance Instruments by calling 888-388-6446 of visit their website at https://advanceinstruments.com.